Accuracy and Bias

Accuracy is the degree of agreement of a measurement (X) with an accepted reference or true value (T); usually expressed as the difference between the two values (X – T), or the difference as a percentage of the reference or true value (100[X – T]/T), and sometimes expressed as a ratio (X/T).

Bias is a systematic (consistent) error in test results. Bias can exist between test results and the true value (absolute bias, or lack of accuracy), or between results from different sources (relative bias). For example, if different laboratories analyze a homogeneous and stable blind sample, the relative biases among the laboratories would be measured by the differences existing among the results from the different laboratories. However, if the true value of the blind sample were known, the absolute bias or lack of accuracy from the true value would be known for each laboratory. See Systematic Error.

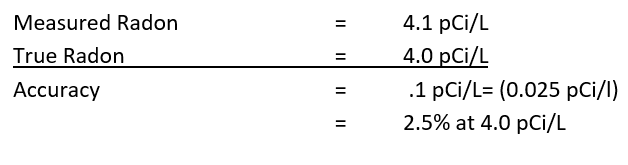

Errors occurring systematically determine the accuracy of a measurement. This is also known as the bias and is calculated by the difference between the result of the measurement and the actual or true radon concentration. It can also be expressed as a percentage error, by dividing this difference by the actual radon concentration. Example:

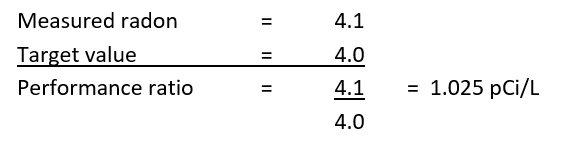

All individual measurements of any device be within 25% of the target value. Accuracy is calculated by dividing the measured value by the true value (“Target” value). The resultant quotient is called the performance ratio. Example (results in pCi/L):

The ±25% accuracy required for each reported measurement translates to a performance ratio that must be between .750 (-25%) and 1.250 (+25%) for each individual measurement.

Systematic errors are errors inserted methodically into the measuring process and show up consistently in every reported measurement. These errors are also called the bias. For example, if there are Active Charcoal kits improperly stored and already recording enough radon for a reading of 1 pCi/L (without even being exposed) then later when the AC’s are used in a house, they will all read +1 pCi/L high.

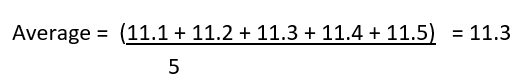

Usually, calculating the bias is not so easy and has to be found by subtracting the average of all the readings from the target value. For example, 5 simultaneous readings are taken of a radon environment:

- 11.1

- 11.2

- 11.3

- 11.4

- 11.5

The systematic error, or bias, is the average of these 5 values subtracted by the target value, which is 10.0 pCi/L. First, the average is found:

The average is then subtracted by the target value:

The bias is 1.3 pCi/L or 12% (1.3/11.3 = 0.115) Until this systematic error is located and corrected, it should be assumed that all measurements with this device are 1.3 pCi/L high.